CUSTOMER STORY - HERATECH

Heratech: BIM at the service of quality engineering.

Share this story

From designing plants and networks to organizing on-site operations and end-of-life material disposal: Autodesk Architecture, Enginering & Construction Collection (AEC Collection) and BIM Collaborate Pro confirm the centrality of their role in process management for multi-utility companies.

The company

The Heratech Engineering Department is responsible for asset design and construction for the Hera Group, one of the largest Italian multi-utility companies in the environmental, energy and water sectors. The Department consists of more than 200 professionals including technicians, engineers, building surveyors, and QC experts, whose specializations range from mechanical, civil, and electrical engineering and automation design to construction, of both plants and networks, and who operate in those three sectors. "Our dedicated design and construction divisions deal with very diverse plants and networks," explained Erika Carloni, head of BIM Development and Coordination, a department created to support designers and site managers throughout the process of changing and integrating operational tools.

The challenge

Heratech's industrial plan currently has approximately 400 projects under development, for a total investment of more than one billion euros. This made it necessary for the company to invest in a digital transformation program set to integrate Building Information Modeling (BIM) processes across the design and construction phases and to standardize technical and management processes. "We are the outcome of the merger of several engineering departments," continued Carloni, "hence the need to define a shared and homogeneous path." BIM, an integral part of a general renewal of tools and platforms, has accelerated this process of digitalization. "We identified BIM as the perfect environment to enable us to grow and improve the quality of our work."

The solution

Following the software selection process and a pilot project launched in 2018, the Autodesk AEC Collection and BIM Collaborate Pro were selected and have since enabled Heratech to initiate and reap the benefits of a transformation process based on BIM and multidimensional, interdisciplinary design models. "Revit and Navisworks, software within the AEC Collection, were used to design the network assets and perform the relevant information checks (model validation, code checking and clash detection). We were able to define a standard data model for each design phase, then use Dynamo to extract all the data we needed to produce the design documents from that model,” explained Giuseppe Viti, engineer and BIM coordinator. The positive results of Heratech's digital transformation program convinced Hera Group to extend its application to facilities management where the use of Revit was approved, and to distribution networks where Civil 3D is currently being trialed.

Collaborative design, one of the strong points of the Autodesk solutions and the BIM approach, enabled Heratech to set up a single common data environment to collect and systematically organize project documentation so that content and information could be shared by all the disciplines involved. "BIM Collaborate Pro enables us to manage all phases of the design process and make all the relevant information available to the various actors involved in the project in real-time," said Marco Pescarini, engineer and CDE manager.

"Working with BIM gives us an enormous advantage, both with the more complex projects that require interference analysis to predict construction site problems, and the simpler but extremely repetitive projects for which we've developed ad-hoc libraries and templates," confirmed Nicola Scomazzon, engineer and BIM coordinator.

"We've already ascertained that the need for amendments to the original project, which previously were flagged on-site, can be reduced by around 4% simply by optimizing the design documents. We expect to reduce planning amendments by 10% as a result of integrated BIM with the other computing systems, our digitization and our process standardization."

—[Erika Carloni], Head of BIM Development and Coordination, Heratech

The advantages

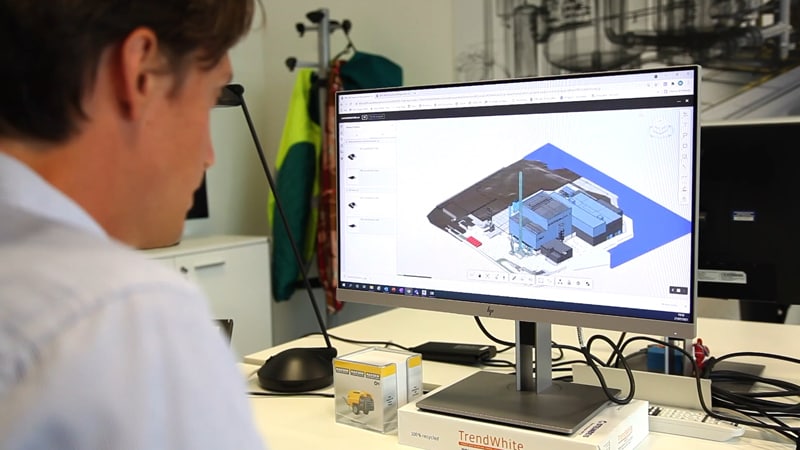

Heratech's next-generation approach to quality engineering is evident at the waste-to-energy plant in Trieste, where work is currently underway. The project involves a complex operation to revamp the existing plant by replacing an incineration line located between two other lines, relocating shared services, and upgrading the heat cycle that serves all three lines for energy recovery by installing a new 2 MW steam turbine that will feed 18.6 MW of electrical power into the grid. All this without interrupting the plant's activity.

It's not hard to imagine the difficulty of the project. " Using the AEC Collection confirmed for us that BIM is fundamental for constructing and managing models of highly complex building sites. Apart from addressing project problems and interference checks, it supports designers and improves the quality of their work,” added Carloni. In fact, carrying out the works while lines were still in operation involved evaluating both design interferences and the on-site access and traffic flow required to keep the plant functioning. "Being able to assess the operational phases and to anticipate and avoid the risk of downtime due to vehicles being parked where they would interfere with the ordinary running of the plant was a major advantage."

Having design and construction in a single shared model enabled all the actors involved and the authorities responsible for issuing permits to fully understand the project. And being able to collaborate on the same basis enabled all the disciplines involved to understand each other's needs. “One factor that makes a difference is the opportunity to get a very clear idea of what the team next to you is doing,” emphasized Carloni. "The Autodesk solutions are truly interdisciplinary, otherwise collaboration would depend entirely on the inclination of the individuals. Now we benefit from it daily.” Thinking in three dimensions and across multiple disciplines simultaneously is one of the main advantages offered by the AEC Collection toolset and makes it possible to pre-empt problems, thereby reducing time and costs. Autodesk BIM Collaborate Pro has provided Heratech with a single shared space containing all the information required to develop site design drawings and identify needs in the field immediately. This advantage translates into decisions that are more easily and accurately shared with customers and therefore can't be contested further down the line.

“The initial investment is higher, but the risks during the construction phase are much lower,” confirmed Carloni. "We expect to reduce planning amendments by 10% as a result of integrated BIM with the other computing systems, our digitization and our process standardization." A model that Heratech is fine-tuning thanks to its experience with plant sites, to enable the Group to do better than ever. “We've already ascertained that the need for amendments to the original project, which previously were flagged on-site, can be reduced by around 4% simply by optimizing the design documents."

Another dimension of BIM is the data and information that enriches the model and makes accurate predictive analysis possible. The sector in which Heratech principally operates, brownfield projects, must necessarily take into consideration all the factors involved in the entire life cycle of a plant. Prior assessment of reusability, sustainability and the costs associated with material disposal is fundamental. "The BIM model provides us with data related to demolition, disposal and recovery of a precision that simply can't be obtained any other way," declared Carloni. "It would be impossible with traditional design methods to obtain the vital information that Autodesk makes available with just a few tweaks to the model.”

Heratech's future will see the integration of BIM and the Autodesk solutions in all the sectors in which the Group operates, an ambitious goal that would be impossible to achieve without the change that the people who are part of the company have helped bring about. “Today the 3D model is our starting point for every project, together with the standardization of what we create,” concluded Carloni. “Thinking in a format stops us sliding backwards from the level we have reached. For our work, uniformity is an added value that leads to ever higher quality."